Case Studies

In The Rotainer

New Gold Inc., Canada shares a logistical solution for adhering to testing and inspection certification when transporting copper concentrate. The research discusses containerised bulk handling and the benefits of the operation. It then discusses in more detail taking samples of the moisture in the copper concentrate and recording the data for its own bulk handling operation.

“The principal objective was to verify the characteristics and behaviour of the copper concentrate during transportation from the mine in Canada to a port. Two access hatches were incorporated into the proposed design of each rotainer lid, for the purpose of obtaining samples for pre-shipment moisture determination in compliance with the IMSBC Code.”

Unloading Urea with Rotating Spreaders on Ship to Shore Cranes

Challenge

With the high demand for fertilizers, RAM Spreaders’ customer wanted to export their urea to a wider global market. The customer’s current infrastructure was too small to accommodate large bulk handling vessels.

Solution

RAM Spreaders worked with the customer and a regional port to export the urea with a containerised bulk handling operation.

“The containerised solution has allowed the customer to export their urea to a wider market of customers with little planning, and investment and without compromising the quality of their commodity.”

Dust prevention in bulk material transportation and handling

Problem: Environmental problems are occurring from dust-generating during the transportation of bulk materials during the transportation and handling.

Solution: The article focuses on several measures used to prevent dust from being generated during transportation and handling, including the RAM Revolver and sealed containers for containerised bulk handling.

“Now it is possible to transport, store and, which is most important, to load bulk cargo into the holds of bulk carriers directly from “the boxes”, i.e. standard

containers.”

Automizing the manual link in maritime supply chains? An analysis of twistlock handling automation in container terminals

Maritime Transport Research has produced an article that takes a qualitative and quantitative approach to the potential barriers, prerequisites and optimization potentials for automating the twistlock handling process in container terminals. The research report considers implementation strategies, their key to success and barriers that container terminals may face. This report signals how the PinSmart automated twistlock handling machine could help ports improve their container handling at the quay crane.

“Impacts on terminal efficiency, cargo handling speed and ship turnaround times are possible […] improvements in labour utilization are promising” Maritime Transport Research (15pg:2021)

CBH turning the tables

Problem: Eti Baker used a rotating tabletop frame system to handle pyrite concentrate at their Mazidagi plant in Mardin, Turkey. The tabletop system was temporary, slow and complex to use.

Solution: Eti Baker looked for a reliable, cost-effective bulk handling solution, which was quick to set up and use in their operations. The RAM Revolver on a reach stacker ticked all these boxes, as well as providing minimal impact to the environment and zero loss of commodity when handled.

“Our revolver customer base has expanded from ship loading to now 50% of orders being inland bulk logistics” –

Cameron Hay, Head of Marketing & Sales

Award Winning Truck to Rail Bi-Modal Containerised Bulk Handling

Problem: At 4,000 meters above sea level, the elevated and remote location of MMG Las Bambas mine posed problems of transporting copper concentrate to market. The team had to find some innovative solutions to achieve a safe and effective method for transporting product to market.

Solution: Following a study, MMG worked with Matarani Port and chose RAM’s Containerised Bulk Handling (CBH) Bi-Modal solution. The solution enabled the transportation of concentrate in special sealed containers 443km by road and 286km by rail to Matarani Port, where it is offloaded from the containers by ‘revolver’ rotating spreader into hopper fed ship loaders.

MMG has indeed set the benchmark for CBH intermodal bulk logistics in South America and won the IBJ Innovative Technology Award in 2016 for a solution that integrated its copper concentrate loading requirements into an existing port infrastructure. Its only a matter of time when this innovative solution becomes common place.

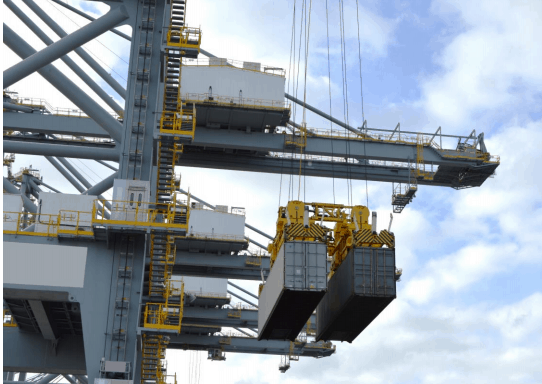

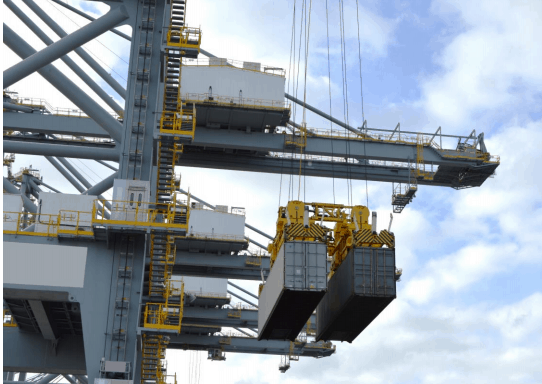

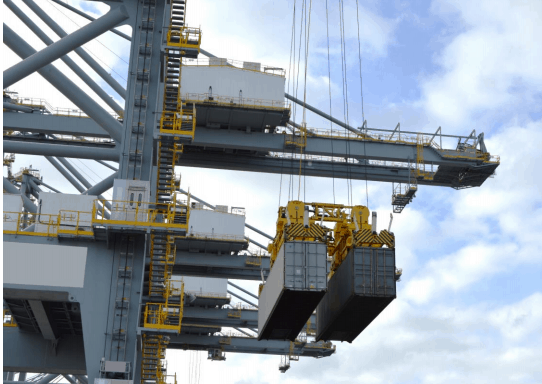

Tandem Lifting Energy Saving Benefits

Problem: With the world transitioning to a sustainable future, the port industry is under pressure to be energy efficient.

Solution: Container terminals are opting for single hoist cranes as they are cheaper to build, weigh less and consume less energy when in tandem operation than dual hoist cranes. But what other benefits will follow?

- Capable of handling 2 x 20/40/45’ or 4 x 20’ containers

- 100 boxes in 50 moves – speeding up quayside operations

- Increased energy efficiency

- Lower crane intensity

- Allows up to 75% multi-lift with more than 40% in tandem

- Spreader change-over in less than 2 minutes without the need for manual intervention.

South American Grain Export Revolution

Problem: Around the world, the global population has continued to surge which reflects the increase in demand for grains like soya. Exporting these grain commodities are a real challenge, as terminals are already working at full capacity and investment for a bulk terminal will be costly.

Solution: A terminal in South America, adopted the ‘Revolver’ Containerised Bulk Handling (CBH) with sealed containers, as it’s cost effective, efficient and protects the value of their customer’s product.

- CBH system allows exporters to take crane to any container terminal

- Lowered logistical costs offsets higher inflation in some Latin American countries.

- No complex ship loading equipment necessary

- Flexible – containers can be re-located to other operation ports with ‘Revolver’ rotating spreader.

Trends in Tandem Lifting

Problem: In this day of mega vessels, tight frame times and endless competition, container terminals are under pressure to handle more whilst not overspending.

Solution: Many terminals have opted for tandem lifting using the SingFlex ship to shore crane headblock, which is a cost-effective solution in comparison to a dual hoist STS crane. SingFlex tandem headblock improves productivity with faster ship operations, shorter berth stays and a more effective use of capital per container.

“We are pleased that the single hoist tandem has allowed DP World to work more productively and as such, attract more business”

Andrew Bowen, Head of Engineering – London Gateway

Low Capital for exporting copper concentrate using ships crane

Problem: The demand for copper is expected to remain high, especially in the electrical and electronics industries. If the right systems for handling copper concentrate are not in place, the quality of the commodity can become degraded, and be lost in the handling process.

Solution: For ports and terminals exporting commodities such as copper concentrate, the capital cost of building a bulk loading infrastructure can be a costly exercise. However, the RAM Revolver on a ship crane was a cost-effective solution.

“Patrick was able to utilize this new revolving spreader technology to export copper concentrate for our client with very little capital”

Adrian Howard – Commercial Director – Patrick Ports & Stevedoring.

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

RAM Spreaders Equipment

Our ship to shore headblock has now been in operation for over 10 years. It was first commissioned at London Gateway in 2012 and since then, the container terminal has made repeat orders with our most popular product the RAM 2940 a ship to shore spreader. The headblock is the most popular on the market due to its low height between sheave pin and twistlock, ease of maintenance, reduced energy consumption and quick changeover between single and twin spreaders. Many container terminals are opting to use the SingFlex headblock with two RAM 2940 spreaders in tandem mode, as opposed to purchasing a new crane due to the significantly higher costs.

Our rotating spreader has also been in operation for over 10 years. The RAM Revolver was first in operation in an Australian container port exporting copper concentrate. The port was impressed with the containerised bulk handling system's ability to export materials efficiently whilst generating zero dust, they also noted on the system's ability to adapt to the port's existing infrastructure. The RAM Revolver is now operational on ship to shore cranes, mobile harbour cranes, ship cranes, reach stackers, bridge cranes and RTG cranes.