Adequate supplies of minerals are essential for constructing, manufacturing and developing new technologies. This is why at RAM Spreaders, we are helping our customers to maximize the efficiency of how bulk materials are handled and avoid any waste during the process.

In the mining sector, the price of the mineral is the volume multiplied by the quality grade. A customer may require a specific grade and quantity. However, the mine can only base their quote on an estimate due to the uncertainty of the mineral grade and quantity that will be delivered to the customer. This is because the quality and grade of any mineral can be jeopardized at any point during a conventional handling process between the pit and port.

RAM Spreaders work with mines and bulk terminals to offer a containerised bulk handling (CBH) solution that improves efficiency and sustainability. For mineral exports, the CBH solution offers an effective way to track and trace the grade quality.

Pit-to-Port Problems

In conventional bulk handling methods, minerals are loaded into open-top wagons and transported via train or truck to the port or drop-off points. It is often the case that bulk minerals are unloaded and reloaded at different drop-off points. Due to how the mineral is handled at these drop-off points, some of it can be unintentionally lost, or its quality is degraded, which can carry substantial financial losses.

When the bulk material arrives at the port, it is stored in open stockpiles or purpose-built warehouses.

Minerals stored in open stockpiles run the risk of cross-contamination, loss of commodity and environmental issues from their exposure to various weather elements.

Whereas bulk warehouses are a better solution, they need to be cleaned after each use to avoid cross-contamination with other bulk materials. This unnecessary cost and task could be avoided with a containerised bulk handling solution.

When it comes to loading, minerals are loaded via grabs or fed by conveyors into the bulk vessel’s hatch. Quality testing of the mineral must be carried out and recorded for the customer during the handling process. Usually, this test is done just before the commodity is loaded into the ship, as there are many factors along the way that could affect the mineral grade.

Containerised Bulk Handling Solution

The mine or processing plant fills containers with mineral or other bulk material in a containerised bulk handling operation. Each container can be filled with up to 30 tons of the commodity (subject to density). The containers are then sealed shut with a removable lid, and the commodity will not see the light of day until it is unloaded into the bulk terminal’s hopper, shipping vessel hatch or another drop-off point.

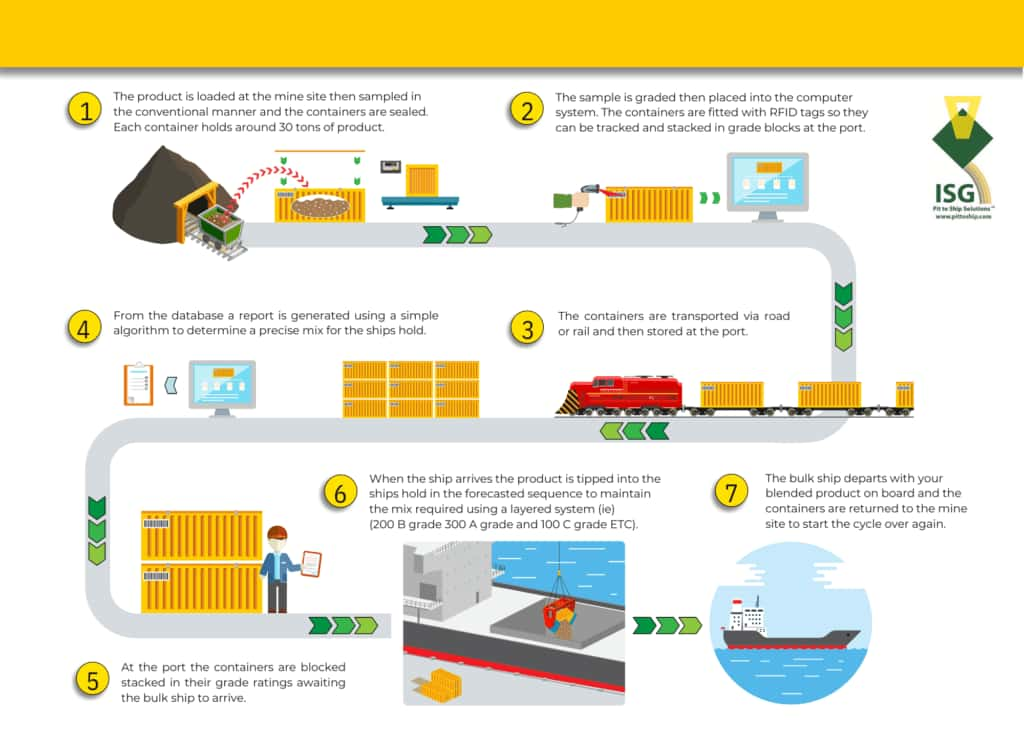

With a containerised bulk handling system, the containers can be fitted with Radio Frequency Identification (RFID) tags to track their journey. The RFID tags allow mines to store information such as the mineral grade and quantity in a database. This data handling system with containerised bulk handling is more efficient and makes pricing for customers more straightforward, as grade quality and quantity remain the same. Specialist container manufacturer Intermodal Solutions Group (ISG) have produced a container flow chart diagram to visualise how RFID tags work.

RAM Spreaders has worked with one customer where the RAM Revolver and sealed containers were used to blend minerals to get the correct grade quality. Once the customer knew the required grade, they blended the minerals, unloaded the minerals into the terminal’s hopper and took a sample on the conveyor system before it entered the shipping vessel.

Over the years, RAM’s CBH solution has won awards for its ability to handle and unload bulk materials sustainably. The sealed containers can be transported via rail or truck, and no dust plumes will generate during their journeys to the port. The same can be said at the port, as the bulk remains in the sealed containers for the arrival of the shipping vessel.

Interestingly, ports that have adopted the containerised bulk handling system require no purpose-built facilities and less space. Containers can be stacked on top of each other, utilising the storage space given more efficiently. As containers are blocked stacked, a particular stack may have a different quality grade or a different commodity than the stack next to it. Thus, different materials/quality grades can be stored and segregated from each other before unloading.

The containers are transported to the quayside via truck when the bulk shipping vessel arrives. The rotating spreader, RAM Revolver, removes the containers from the truck, moves them towards the hatch and removes the sealed lid. Once the rotating spreader has lowered the container into the hatch, it rotates 360 degrees decanting the minerals and then replaces the lid onto the container. The container is then placed back onto the truck, and the cycle is repeated. Some of our customers have opted to include a misting system fitted to the ship’s hatch, which further deters dust plumes from generating when unloading the bulk materials.

Frequently Asked Questions

What is the RAM Revolver?

The RAM Revolver is a rotating spreader that is used to unload containers with bulk materials. It removes the containers from the truck, moves them towards the hatch and removes the sealed lid. Then it lowers the container into the hatch, rotates 360 degrees decanting the minerals and then replaces the lid onto the container. The container is then placed back onto the truck, and the cycle is repeated.

What commodities can be transported with CBH?

Any dry bulk material. RAM Spreaders has worked with a wide range of materials including copper concentrate, grains, zinc, wood pellets, wheat, sugar, etc. The RAM Spreaders’ team just need to work out the product design and weight to determine which container design and RAM Revolver design would be suited for your operations.

How does quality grade tracking improve the efficiency of CBH?

Quality grade tracking allows for precise control over the blending of different grades of commodities. By knowing the exact grade and quantity in each container, operators can mix different containers to achieve the desired grade quality. This eliminates the need for additional blending facilities and reduces the time and cost of handling.