RAM4200 Pipe Spreader

Telescopic

Pipe Spreader

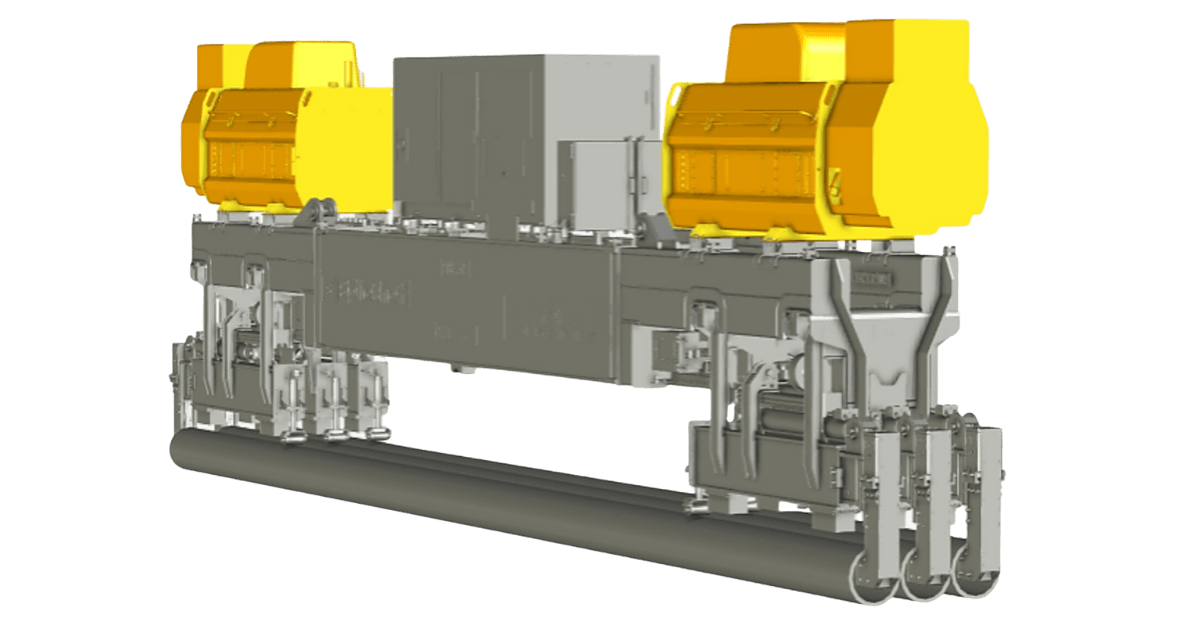

The RAM4200 is a telescopic pipe handling spreader designed for MHCs, ship cranes, reach stackers and other overhead cranes. The spreader tackles the manual process of handling pipes, which can be a slow and dangerous task.

The pipe spreader has the power to handle a wide range of pipe lengths and diameters. The spreader is powered by an onboard diesel engine and operated by a wireless remote control.

Its four telescopic beams with end manipulators move along a longitudinal axis, enabling the spreader to handle pipes between 1150cm to 1300cm in length.

Lateral adjustments and removal of the central beams allow the crane operator to handle a variety of pipe diameters with ease - 3 x 16-32 inch pipes / 2 x 32-60 inch pipes or 1 x 16-60 inch.

The spreader's mechanical sensing assemblies coupled with LED indicators reassure the crane operator that pipes are securely clamped and ready for hoisting.

Purpose-built padding rings located on the end manipulators and additional padding on each of the spreader's pipe contact points help prevent pipe damage during the handling process.

Monitoring sensor status and fault-finding information is carried out via a diagnostic panel providing maintenance personnel troubleshooting information.

Technical

|

Lifting Config |

Pipe Length (m) |

Pipe Diameter (inches) |

| 3 beam | 11.8m-12.7m | 19-35 |

| 2 beam | 11.8m-12.7m | 36-60 |

| 1 beam | 11.8m-12.7m | 16-60 |

Benefits

Improve operational safety

As the telescopic beams clamp the pipes, there is no danger of the pipes falling when lifting. In addition, the spreader’s mechanical sensors and LED indicators signal the crane operator to notify when the pipes are securely clamped.

More efficient cycle

Due to its design, the spreader can handle a number of pipes at the same time; it can also retract and extend depending on the geometrics of the pipe. Moreover, with the spreader’s memory positioning system (MPS), the spreader will log the positions of the telescopic arms into the system’s memory. Thus, MPS can store a landside and a seaside position, enabling the crane operator to return to either of these positions.

Protects pipe integrity

At the end of each telescopic beam is purpose-built padding rings to prevent the pipe from being damaged in operation.

Media

Press Articles

Pipe handling challenges and solutions

The realisation of RAM’s pipe dream

Videos

Further Info

Certification

All RAM spreaders are manufactured at our purpose built production facility in accordance with ISO 9001:2008:2008, ISO 14001;2004 and DIN 18800-7 welding standard.

Fully Tested

All spreaders are fully load tested, function tested and are delivered together with operation and maintenance manuals and associated certification.

Warranty

All RAM Spreader products are supplied with full equipment warranty.