Shipping vessels carry thousands of containers each journey. Turning this high volume into profit is no easy task, it requires a well-oiled operation with the right tools. With over 120 SingFlex’s now in operation at major terminals around the world and more on order, the RAM tandem headblock is the most effective on the market.

Move More & Save Big

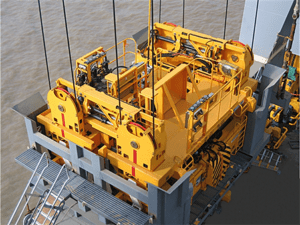

SingFlex is a headblock that allows two container spreaders to attach to a single hoist crane and provide the terminal with tandem lift capability. With this power, terminals can handle in single lift spreader mode 20ft/30ft/40ft/45ft ISO containers (subject to spreader capability) or alternatively in twin lift spreader mode 2 x 20ft / 2 x 40ft / 2 x 30ft or 4 x 20ft ISO containers.

With the cost of energy soaring and CO2 emissions being a hot potato, we should all reduce our energy consumption. Reducing lift cycle per hour means container spreaders work less, cranes work less and thus energy consumption is less. A case study comparing single lifting or tandem lifting of 125 tons loaded containers shows an energy saving of 15%-20% when in tandem mode. Therefore, we can derive that the SingFlex not only increases productivity but reduces cost and drives up revenue.

First Class Features

Chances are your crane operator will encounter challenges with from cycle to cycle, you could be handling two 40ft containers in one cycle and, in the next, four 20ft containers. Or, your trucks delivering the containers to the quay side are spread further apart. The key is to adapt, quickly. At RAM, we take all this into consideration when designing our products. The SingFlex allows the operator to adjust the height difference (+/- 500mm), longitudinal offset (+/- 200mm), gap (0-1600mm) and the relative skew (+/- 3 degrees). These features ensure that a safe and swift handling of the containers.

It is common for crane operators to change over from single spreader to twin spreaders, when they see several containers in a row on a vessel. They see the speed and efficiency that lifting more containers can bring. Understandably, they will want a quick changeover from single to twin spreaders. SingFlex has the quickest change. It has no need for manual intervention. Within 2 minutes, the crane operator can go from single spreader to twin spreader.

The SingFlex docking station is used for storing the secondary headblock, its spreader and it is the location where the rapid change-over is made from single to tandem spreader (vice versa). Over the years, the headblock has evolved project by project to speed up the changeover. Now, it is tailored for the Ram 2940 spreader with its unique flipper arrangement developed for tandem operations.

The Journey So Far

RAM’s SingFlex tandem headblock is not a complicated solution. In fact, it has a low height advantage over competitor models, with just three metres from sheeve pin to the bottom of the spreader*. This allows our customers in London, Antwerp, Rotterdam, Le Havre, Doha, Jebel Ali, Lazaro Cardenas, Qingdao, Yangshan, etc., to accommodate larger vessels without the need to increase their height of their cranes.

Moreover, a report commissioned by the world’s largest port Shanghai SIP analysed the operations of dual hoist STS operations and single hoist tandem. The report found that dual hoist operations had high energy consumption and low utilization. Whereas, single hoist tandem operations were lower priced, weight, energy consumption and had a higher utilization (>40%). Knowing this information, we are optimistic about the SingFlex’s future.